- Home

- /

- Services

Condensate Recovery

Condensate Recovery

Condensate Recovery

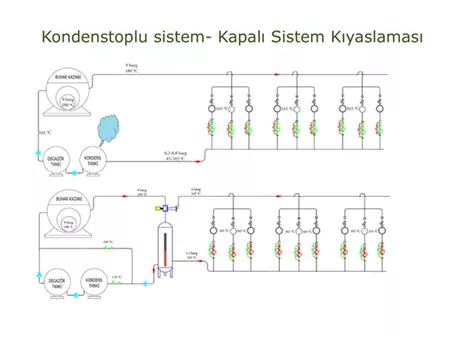

Condensate recovery is the process of collecting and reusing hot water resulting from the condensation of steam after it is used for heating or process systems. Condensate is basically pure water that contains a lot of heat energy. By returning this to the boiler feed water system, energy, water and money are saved. Condensate recovery provides many benefits for your steam system and your business. These;

Energy Savings: When you reuse condensate, you reduce the amount of fuel needed to produce steam. This reduces your energy costs and carbon footprint. Condensate has a higher temperature than outdoor or mains water, so it requires less heat to boil. Returning the condensate to the boiler without venting it to the atmosphere saves a minimum of 22% of the fuel input.

Boiler Feed Water Savings: When you reuse condensate, you reduce the amount of fresh water required to compensate for losses in the steam system. This reduces your water costs and environmental impact. Water is a scarce and valuable resource and should be used wisely and efficiently. It saves approximately 70% water.

Chemical Savings: When you reuse condensate, you reduce the amount of chemicals needed to treat boiler feed water. This reduces your chemical costs and waste disposal costs. Condensate is pure water and has low levels of dissolved solids and gases. It requires much less processing than raw water to prevent corrosion and burrs in the boiler. Therefore, it provides 70% chemical savings.

Equipment Depreciation Savings: When you reuse condensate, you protect your steam equipment from damage caused by thermal shock, corrosion and erosion. This extends equipment life and reduces maintenance costs. Condensate has a similar temperature and pressure as the steam it comes from, so it does not cause sudden changes in system conditions. Condensate also has a neutral pH and low oxygen content, so it does not erode or corrode metal surfaces. There is no need to use a steam trap.

The condensate recovery system consists of several components that collect condensate and flash steam and return them to the boiler feed water system.

-A pressurized tank

-Steam pump

-Level indicator and automatic valves

-Control Panel

How can we help you with our condensate recovery system?

We specialize in designing, installing and maintaining condensate recovery systems for a variety of industries and applications. We help you optimize your steam system performance and efficiency.

- Minimum 22% fuel saving

- 70% savings in boiler feed water and chemical usage

- A comprehensive assessment of your existing steam system and its improvement potential

- A tailored solution to suit your needs and goals

- A high-quality installation ensuring safety and reliability

- There is no need to use a steam trap

- A regular maintenance service that prevents problems and extends equipment life

- A continuous support service that answers your questions and solves your problems

If you would like to get more information about condensate recovery systems and services, just contact us. We would like to meet with you and help you achieve your energy efficiency goals.

Join Our Newsletter

Be informed about innovations about us