Name of the Product You Will Order: Economizer

Economizer

Economizer

Economizer

In today's competitive business world, manufacturers are constantly searching for solutions to optimize their operations, increase energy efficiency and reduce costs. An area where significant savings can be achieved in this regard is in the field of energy consumption. This is where economizers come into play. Economizers are smart devices that allow manufacturers to increase energy efficiency by using waste heat generated during industrial processes. By integrating economizers into their business processes, manufacturers can not only reduce their environmental impact but also enjoy significant financial benefits.

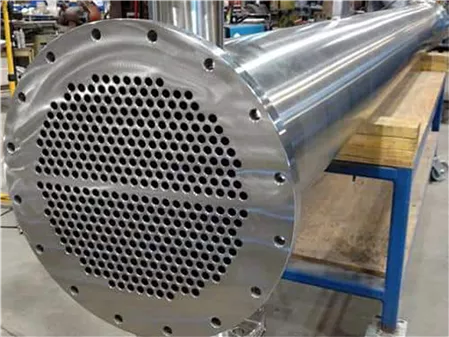

Economizer is a type of heat exchanger that recovers waste heat from exhaust gases or flue gases generated during various production processes. Rather than losing this waste heat energy, it captures it and transfers it to another medium, usually water or air. By reusing this waste heat, manufacturers can significantly reduce the amount of additional energy required for their operations, thus achieving significant cost savings.

How Do Economizers Work ?

Economizers are based on a simple but highly effective principle. They recover the heat of the exhaust gases through a heat exchanger. The heat exchanger transfers the recovered heat to another fluid medium, such as water or air. This water or air can be used for preheating applications or steam generation. By preheating incoming feed water or combustion air, it reduces energy demand on traditional sources such as boilers or heaters. This process optimizes energy use and minimizes the overall energy consumption of the production facility.

Advantages of Economizers

1. Increased Energy Efficiency: By utilizing waste heat, economizers enable manufacturers to achieve higher levels of energy efficiency. This reduces energy consumption and lowers operating costs in the long run.

2. Cost Savings: One of the key advantages of economizers is their potential cost savings. By using waste heat and reducing dependence on traditional energy sources, manufacturers can realize significant savings on their energy bills. These gains have a positive impact on profit margins and increase the overall financial health of the business.

3. Environmental Sustainability: Besides cost savings, economizers also contribute to a greener and sustainable production process. By reusing waste heat, manufacturers can significantly reduce their carbon footprint and minimize their overall environmental impact. This not only aligns with corporate social responsibility objectives, but also strengthens the company's reputation as an environmentally responsible organization.

4. Improved Equipment Life: Integration of economizers can help reduce the load on other energy-intensive equipment such as boilers and heaters. By preheating the feed water or combustion air, the load on these systems is reduced, which reduces wear. This can extend the life of the equipment and minimize the need for costly repairs or replacements.

5. Regulatory Compliance: Many countries and regions have strict energy efficiency regulations to promote sustainable practices. By implementing economizers, manufacturers can ensure compliance with these regulations and avoid potential penalties.