Name of the Product You Will Order: Storage Tanks

Storage Tanks

Storage Tanks

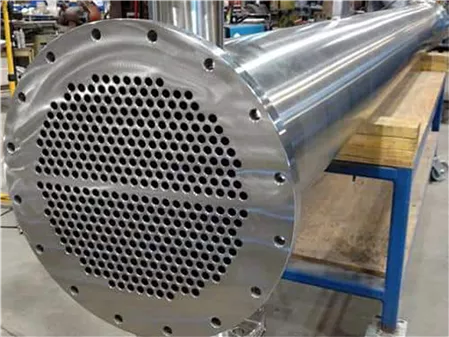

Chemical and Raw Material Storage Tanks

In the manufacturing industry, the storage and processing of chemicals and raw materials plays a critical role in maintaining operational efficiency and the safety of employees and the environment. Chemical and raw material storage tanks play an important role in providing a safe environment for the safe and controlled storage of various substances. In this article, we will explore the importance of these storage tanks and touch upon the advantages they provide for manufacturers.

1. Protecting Personnel and the Environment:

When it comes to storing chemicals and raw materials, safety is one of the most important factors. These substances can be hazardous if handled incorrectly or exposed to improper storage conditions. Storage tanks provide a reliable and safe solution by minimizing leaks, spills and accidents. Its robust structure, corrosion-resistant materials and advanced safety features ensure that harmful substances are kept inside the tank, thus protecting personnel and the environment.

2. Protecting Product Integrity:

Many manufacturing processes depend on the quality and consistency of raw materials and chemicals. The right storage tanks help maintain the integrity of these substances and protect them against external factors that could compromise their quality. Factors such as temperature, humidity, light exposure, and contamination can affect the stability and composition of chemicals. Well-designed storage tanks minimize these risks and provide manufacturers with access to reliable and uncontaminated materials for their production processes.

3. Maximizing Efficiency and Availability:

Efficient storage and processing of chemicals and raw materials is vital to smooth-running manufacturing operations. Storage tanks are designed to optimize accessibility so that materials can be easily retrieved when needed. Tank systems organized with correct labeling and tracking systems ensure that materials are easily found, reduce wasted time and increase overall efficiency. Additionally, advanced monitoring technologies can be integrated into tanks, providing real-time data on stock levels, allowing producers to effectively plan and manage their resources.

4. Customized Solutions Adaptable to Different Needs:

Manufacturers have a variety of needs when it comes to storing chemicals and raw materials. The good news is that storage tank solutions can be customized to meet specific needs. Tanks can be designed to accommodate a variety of volumes, from small-scale operations to large-scale industrial facilities. Additionally, storage tanks can be constructed using different materials such as stainless steel, fiberglass or polyethylene, depending on the compatibility of the substances being stored. Customizable options also include special fittings, coatings and insulation, ensuring optimal storage conditions for specific materials.

5. Compliance with Regulatory Standards:

The manufacturing industry is subject to strict regulations on the storage and processing of chemicals and raw materials. Storage tanks that meet industry standards and regulatory requirements are important for manufacturers to remain compliant. Working with reputable tank manufacturers who understand these regulations ensures that storage tanks are designed and built to the highest safety standards, reducing the risk of regulatory violations and associated penalties.