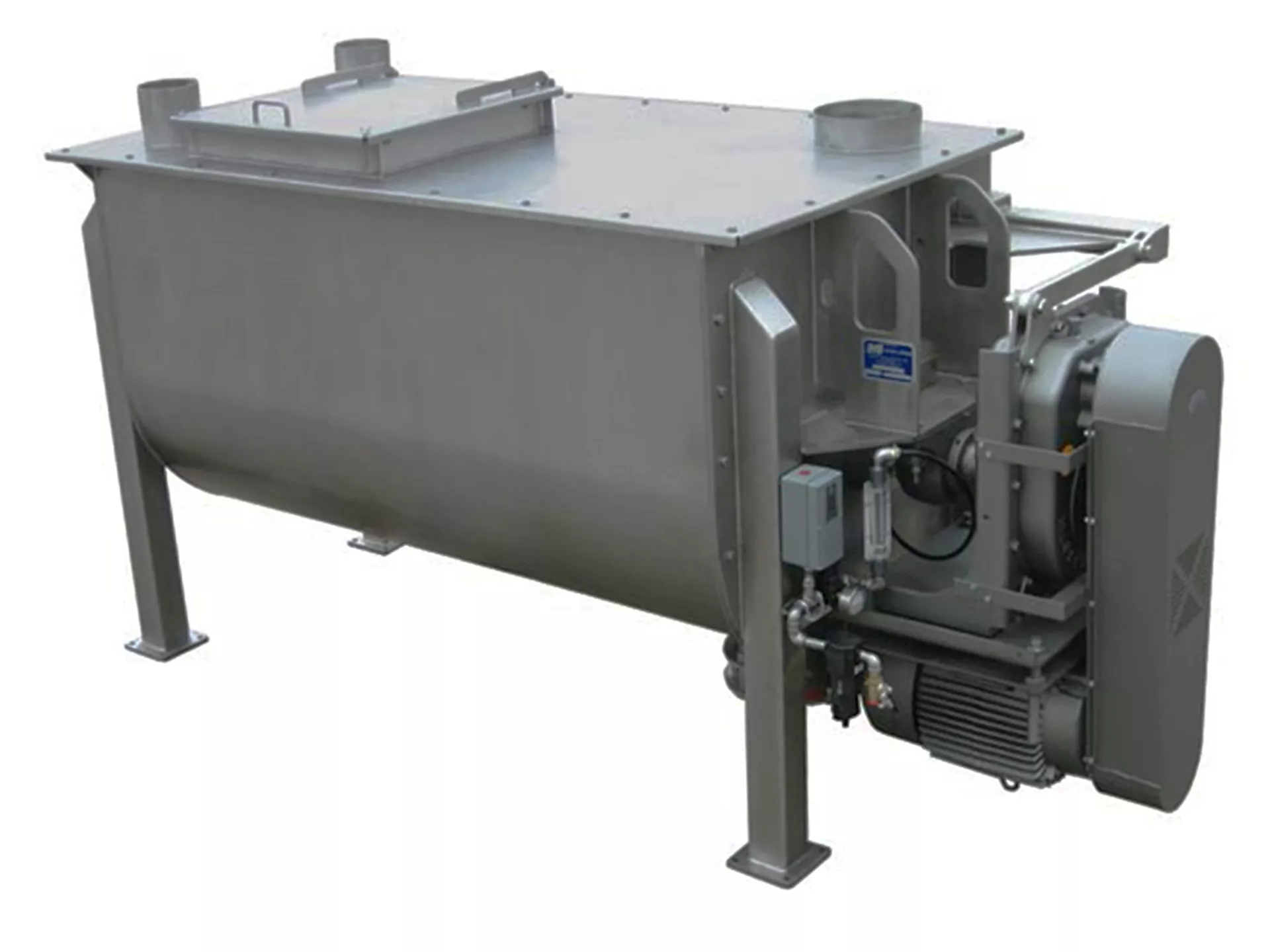

Name of the Product You Will Order: Mixer

Mixer

Mixer

Industrial Mixers

Industrial mixers have become indispensable tools for manufacturers looking to optimize their production processes. By offering efficiency, precision, versatility and innovative technologies, these mixers help businesses optimize operations, maintain product consistency and increase customer satisfaction. In an environment where industries are constantly evolving, investing in high-quality industrial mixers will be vital to staying ahead of the competition and maintaining success in the dynamic global marketplace.

As Mektron Machinery,

-Jacket heating and cooling,

-Serpentine heating and cooling,

-We manufacture and design mixers such as single reducer, double blade.

Benefits of Using a Mixer

Improved Efficiency:

Industrial mixers are designed to facilitate production by mixing raw materials effectively, obtain a homogeneous product and reduce processing time. Thanks to advanced mixing technologies, manufacturers can achieve high-speed and thorough mixing, providing a homogeneous product with minimal effort. Whether powders, liquids, pastes or liquid-solid mixtures, industrial mixers offer flexibility in processing a variety of materials, increasing the efficiency of the production line.

Increased Sensitivity:

Precision is of great importance in many sectors. Industrial mixers allow manufacturers to achieve consistent results and maintain product integrity by providing precise control over variables such as mixing speed, temperature and force values. Thanks to programmable settings and automatic features, modern mixers offer the opportunity to achieve precise dosing and mixing ratios, thus reducing the risk of errors and product variations. This level of precision helps manufacturers meet stringent quality standards and comply with regulatory requirements, while increasing customer satisfaction and brand reputation.

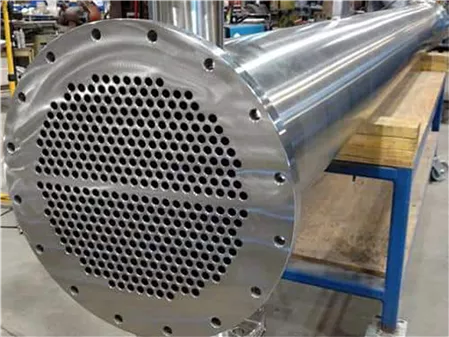

Diversity in Application Areas:

Industrial mixers have a wide range of applications to meet different needs in every industry. In the pharmaceutical industry, mixers are used to provide homogeneous drug formulations of active ingredient (API), excipients and other additives. In the food and beverage industry, mixers play an important role in creating consistent recipes, emulsifying ingredients and optimizing texture and flavor. Additionally, mixers are indispensable in chemical production, cosmetics production, paints and coatings and various other industries, which demonstrates their flexibility and adaptability.

Innovative Technologies:

The evolution of industrial mixers has been followed by continuous innovations, resulting in the emergence of cutting-edge technologies. Manufacturers can now choose from a variety of mixer types, such as tire blenders, paddle mixers, high shear mixers, planetary mixers and more, each targeted towards specific applications. Additionally, advances in automation, sensor technology and data analytics have led to the development of smart mixers with features such as self-tuning, real-time monitoring and remote control. These innovations increase productivity, minimize downtime and aid proactive maintenance planning.

Customization and Scalability:

Every manufacturing process is unique and industrial mixers can be customized to meet specific requirements. Manufacturers can choose from a variety of sizes, construction materials, mixing mechanisms and additional features to optimize the mixer's performance. What's more, industrial mixers can be easily integrated into existing production lines or designed as standalone units, providing the ability to scale as businesses grow or diversify their operations. The ability to customize and scale allows industrial mixers to adapt to changing industry demands, thus remaining a long-term investment.