Name of the Product You Will Order: Reactor

Reactor

Reactor

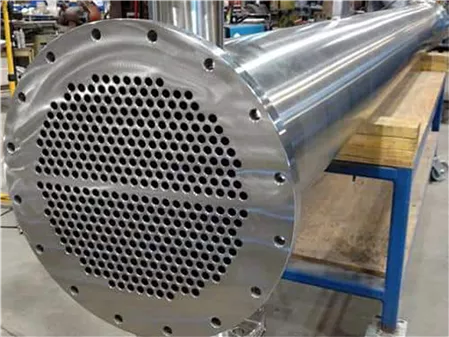

Chemical Reactors

Chemical reactors play a critical role in the manufacturing industry, transforming raw materials into valuable substances through controlled chemical reactions. These reactors are used as a key component in the production of many products and enable the production of many products that affect our daily lives. Manufacturers are increasingly considering the use of advanced chemical reactors to achieve targets in terms of efficiency, sustainability and product quality.

Our Browsing Features.

- ASME “U” Mark & NBIC “R” Certificate

- Low and high pressure designs

- 100% Radiography

- PMI - Positive Material Identification

- Pickling and Passivation (Citric, Nitric and Phosphoric Acid)

- Heat treatment and Stress relief

- Thermal insulation with stainless and aluminum coating

1. Precise Control and Optimization

Chemical reactors provide precise control and optimization of chemical reactions, ensuring that the desired product is consistently obtained at the same quality. Advanced reactor designs, such as continuous flow reactors and stirred tank reactors, offer better mixing capabilities, temperature control, and reaction time management. Being able to control reaction parameters allows manufacturers to maximize efficiency, reduce unwanted byproducts, and increase selectivity. This makes the process more efficient and cost effective.

2. Safety and Environmental Impact

Safety and environmental concerns are critical in the manufacturing industry. Chemical reactors with advanced safety features and control systems help reduce potential risks associated with reactive chemicals and exothermic reactions. Improved temperature control, pressure relief mechanisms and advanced monitoring systems allow manufacturers to maintain optimal operating conditions and prevent undesirable events. Additionally, modern reactor designs include sustainability features such as waste reduction and energy-efficient technologies, reducing the environmental impact of industrial processes.

3. Process Intensification and Scalability

Chemical reactors aid in process intensification, enabling manufacturers to achieve higher production rates and reduce resource consumption. Advanced reactor technologies, such as microreactors and catalytic reactors, reduce reaction times and enable smaller reactor volumes by increasing heat and mass transfer efficiency. This reduces raw material requirements, energy consumption and waste production, as well as optimizing space usage. Additionally, scalable reactor designs provide manufacturers with the flexibility to adapt and expand production capacities according to their needs.

4. Catalyst Development and Optimization

Catalysts are an essential component of many chemical reactions, and chemical reactors serve as a platform for catalyst development and optimization. Integrating catalysts into reactors makes it possible to achieve desired product properties by increasing the reaction rate and selectivity. Advanced catalyst coated reactor systems, such as fixed bed reactors or fluidized bed reactors, provide excellent control over catalyst performance, thus maximizing productivity and minimizing catalyst degradation. This improves process economics and reduces environmental impact.

5. Process Monitoring and Control

Accurate process monitoring and control is important to maintain product quality and ensure continuous performance. Modern chemical reactors are integrated with advanced instrumentation and automation technologies that offer real-time monitoring. Instant monitoring of reaction parameters such as temperature, pressure, pH and composition provides precise control and adjustment. Manufacturers can quickly detect process deviations and take corrective measures, minimizing production disruptions and improving product quality.