Name of the Product You Will Order: Pressure Vessels

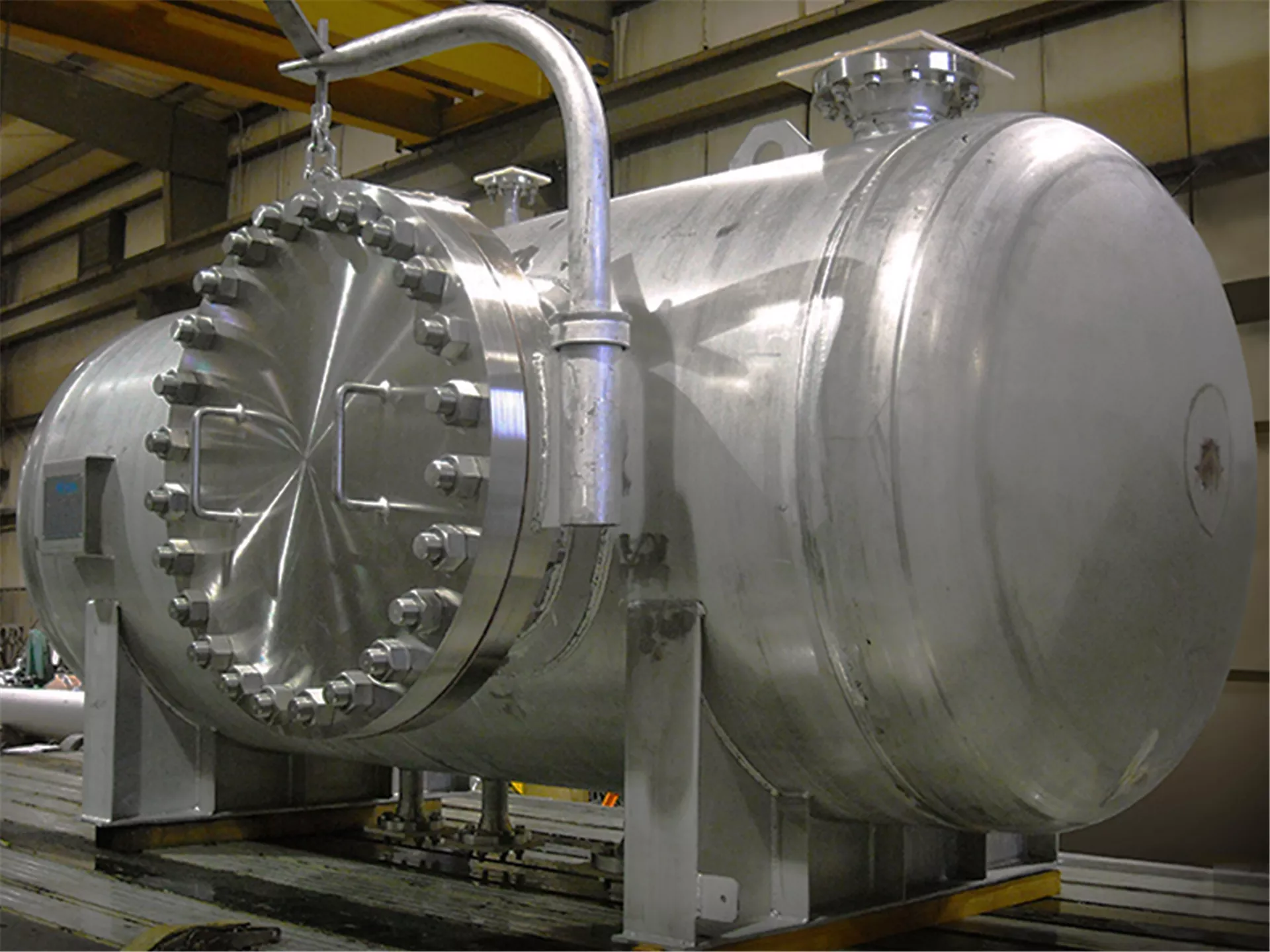

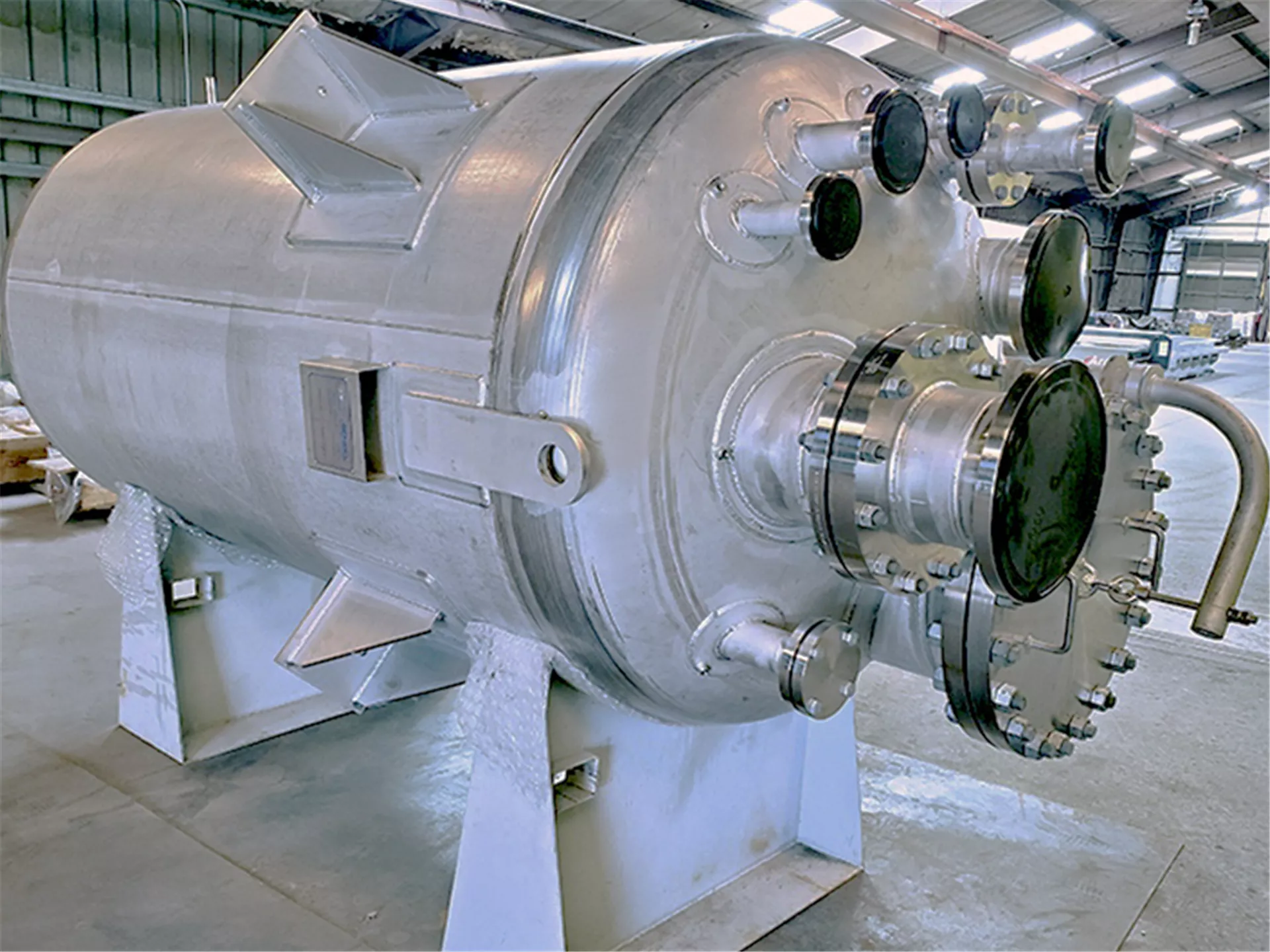

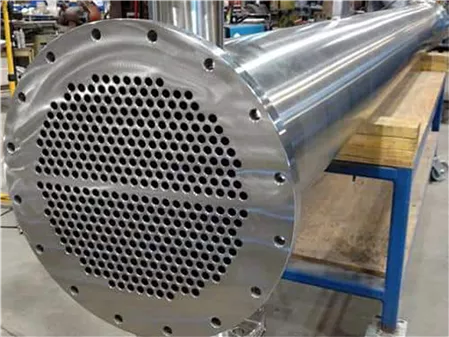

Pressure Vessels

Pressure Vessels

Pressure Vessels

Pressure vessels have become indispensable components in modern production processes. They ensure safe and efficient processing of substances under high pressure. Versatility, compatibility and compliance with stringent industry standards make pressure vessels indispensable tools for manufacturers in different industries. Investing in high-quality pressure vessels and prioritizing safety and reliability helps manufacturers optimize their operations, increase productivity and maintain the integrity of their products.

- ASME “U” Mark & NBIC “R” Certificate

- Atmospheric, Low and high pressure designs

- 100% Radiography tests

- PMI - Positive Material Identification

- Pickling and Passivation (Citric, Nitric and Phosphoric Acid)

- Heat treatment and Stress relief

- Insulation with stainless, aluminum and fiberglass coating

- Jackets (Half Pipe, Dimpled, Conventional)

- Internal Pipe Rolls heating or cooling

Ensuring Security and Reliability

One of the main functions of pressure vessels is to ensure the safety and reliability of industrial processes. These containers are manufactured with sturdy materials and meticulous design to withstand high internal pressure and prevent potential leaks or explosions, preventing catastrophic accidents. Manufacturers comply with stringent industry standards and regulations, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Guidelines, thereby ensuring the integrity and performance of pressure vessels.

Versatility and Convenience

Pressure vessels provide manufacturers with a versatile and adaptable structure, offering a wide range of applications. These containers can be custom designed to fit specific production needs and can accommodate a variety of shapes, sizes and pressure requirements. From storing and transporting gases, liquids, and chemicals to heat exchanges and catalytic reactions, pressure vessels serve as indispensable tools in many industries.

Increasing Efficiency and Productivity

By using pressure vessels, manufacturers can increase operating efficiency and productivity. These containers allow substances to be stored under high pressure, reducing the space required for large storage tanks. This effective use of space allows manufacturers to optimize facility layout, allocate resources more effectively and streamline production processes. Additionally, pressure vessels increase production efficiency by facilitating faster reactions and reactions occurring at higher temperatures.

Protecting Product Integrity

Some manufacturing processes require precise and controlled environments to maintain the integrity of products. Pressure vessels provide manufacturers with the ability to create such controlled environments. For example, in the pharmaceutical industry, pressure vessels are used in sterilization processes and aseptic processes for the safety and effectiveness of drugs. Similarly, in the food and beverage industry, pressure vessels are used in pasteurization and preservation processes to ensure product quality and extend shelf life.

Compliance with Industry Standards

Pressure vessels are subject to strict industry regulations and standards to ensure safety and reliability. Manufacturers must comply with standards such as ASME, which specify design, manufacturing and testing requirements. Compliance with these standards ensures the integrity of pressure vessels as well as helping manufacturers maintain compliance with legal and regulatory requirements. This commitment to quality and safety enhances manufacturers' reputation and gives confidence to their customers and stakeholders.